Founded in 1976, and located on Anhanguera Highway, in the town of Cravinhos, State of São Paulo, it has 16,000m² of built area on a plot of land of 173,000m². The company is fitted with the most advanced equipment, most of which imported, with facilities specially designed to provide maximum efficiency in all production areas.

Zanini Renk is interlocked with the environment and social aspects. From the social Project, with the insertion of young people in the labor market, to the reforestation of riparian vegetation, Zanini Renk is engaged in generating actions and projects focused on the direction to a sustainable future.

Qualifying and training future leaderships also are principles of Zanini Renk Academy, moving young people to professional enhancement.

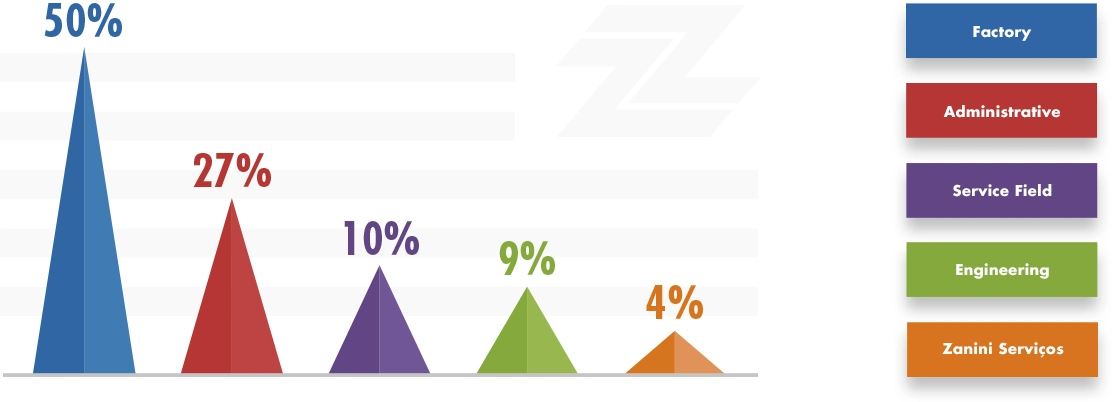

Our employees are extremely important for Zanini Renk’s success, they are the ones who manage and run the company; they are the ones who control and execute activities and processes.

This is the reason Zanini Renk pays special attention to human resources development, aiming to find and use talents in the most varied activities of the organization.